The Complete Guide to Sensor Monitoring in Wastewater Systems: Maximizing Efficiency and Compliance

In today's complex wastewater management landscape, sensor monitoring has become the backbone of efficient operations. As treatment facilities face increasing demands for operational efficiency and regulatory compliance, understanding and implementing effective sensor monitoring systems is no longer optional—it's essential for success.

Understanding Sensor Monitoring in Wastewater Operations

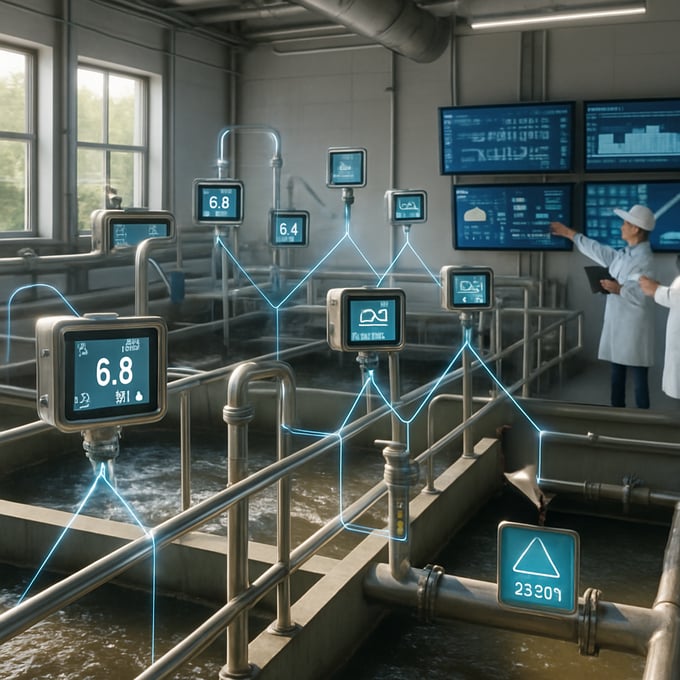

Sensor monitoring encompasses the continuous measurement and analysis of various parameters crucial to wastewater treatment processes. These sophisticated systems provide real-time data that enables operators to make informed decisions, prevent system failures, and maintain optimal performance levels.

Key Parameters Monitored by Wastewater Sensors

| Parameter | Importance | Typical Range |

|---|---|---|

| pH Level | Critical for biological treatment processes | 6.5-8.5 |

| Dissolved Oxygen | Essential for aerobic treatment | 2-4 mg/L |

| Turbidity | Indicates treatment effectiveness | < 1 NTU (finished water) |

| Flow Rate | Critical for process control | Facility-specific |

Benefits of Advanced Sensor Monitoring Systems

Modern sensor monitoring solutions offer numerous advantages that directly impact operational efficiency and regulatory compliance:

1. Real-Time Data Analysis

Advanced monitoring systems, like RACO's Catalyst™, provide instantaneous access to critical operational data. This real-time capability allows operators to:

- Identify potential issues before they become problems - Make immediate process adjustments - Maintain optimal treatment conditions - Reduce energy consumption through precise control2. Remote Monitoring Capabilities

The ability to monitor systems remotely has revolutionized wastewater management. Operators can now:

- Access system data from anywhere with internet connectivity - Receive instant alerts about system anomalies - Adjust parameters remotely when necessary - Reduce on-site staffing requirementsEssential Components of an Effective Sensor Monitoring System

1. Sensor Networks

A comprehensive sensor network typically includes:

| Sensor Type | Function | Critical Applications |

|---|---|---|

| Level Sensors | Monitor liquid levels in tanks and basins | Overflow prevention, pump control |

| Flow Meters | Measure fluid movement through system | Process control, compliance reporting |

| Chemical Sensors | Monitor chemical parameters | Treatment optimization, safety monitoring |

2. Data Collection and Analysis Systems

Modern monitoring solutions must include robust data management capabilities:

- Automated data collection and storage - Advanced analytics for trend identification - Custom reporting capabilities - Integration with existing SCADA systemsImplementing Effective Sensor Monitoring Solutions

Best Practices for System Design

When designing a sensor monitoring system, consider these crucial factors:

| Design Element | Consideration | Impact |

|---|---|---|

| Sensor Placement | Strategic location for accurate readings | Data accuracy, system effectiveness |

| Communication Infrastructure | Reliable data transmission | System reliability, response time |

| Redundancy | Backup systems and fail-safes | System reliability, compliance |

Maintenance and Calibration Requirements

Regular maintenance is crucial for sensor monitoring system reliability:

Maintenance Schedule Components

- Daily visual inspections - Weekly calibration checks - Monthly comprehensive testing - Quarterly professional servicingFuture Trends in Sensor Monitoring

The field of sensor monitoring continues to evolve with emerging technologies:

Emerging Technologies

- AI-powered predictive analytics - IoT integration for enhanced connectivity - Advanced self-calibrating sensors - Machine learning for pattern recognitionMaking the Right Choice for Your Facility

Selecting the appropriate sensor monitoring system requires careful consideration of several factors:

| Factor | Considerations | Impact on Decision |

|---|---|---|

| Facility Size | Treatment capacity, number of monitoring points | System scale and complexity |

| Budget | Initial investment, ongoing maintenance costs | System selection and features |

| Regulatory Requirements | Compliance needs, reporting requirements | System capabilities and certifications |

Conclusion

Effective sensor monitoring is crucial for modern wastewater treatment facilities. By implementing comprehensive monitoring solutions like those offered by RACO Manufacturing & Engineering, facilities can ensure optimal operation, regulatory compliance, and efficient resource utilization. The key is selecting and maintaining the right system for your specific needs while staying current with emerging technologies and best practices.

For more information about implementing effective sensor monitoring solutions in your facility, contact RACO's expert team or explore our range of advanced monitoring systems designed specifically for wastewater applications.