The Ultimate Guide to Preventative Maintenance for Technicians in the Stormwater Industry

In the stormwater industry, preventative maintenance plays a vital role in ensuring the efficient functioning of systems and preventing costly repairs or replacements. Understanding the importance of preventative maintenance is crucial for technicians working in this field. By implementing regular maintenance practices, technicians can minimize the risk of equipment failure, improve system performance, and prolong the lifespan of stormwater infrastructure.

Understanding the Importance of Preventative Maintenance

Preventative maintenance involves performing routine inspections, cleaning, and repairs to identify and address potential issues before they escalate. In the stormwater industry, where systems are constantly exposed to harsh weather conditions and environmental factors, this proactive approach to maintenance is essential.

By engaging in preventative maintenance, technicians can detect early signs of wear and tear, corrosion, or blockages. By addressing these issues promptly, they can prevent extensive damage that could lead to system failure or costly repairs.

Furthermore, preventative maintenance plays a crucial role in ensuring the safety and functionality of stormwater infrastructure. Regular inspections help to identify potential hazards, such as unstable structures or compromised drainage systems, which could pose a risk to public safety. By addressing these issues proactively, technicians can mitigate the risk of accidents or injuries.

The Role of Preventative Maintenance in the Stormwater Industry

In the stormwater industry, preventative maintenance serves as a proactive measure to preserve the integrity and functionality of stormwater infrastructure. Regular inspections and maintenance activities help to identify and rectify problems such as clogged drains, damaged pipes, or malfunctioning pumps.

By monitoring the condition of stormwater systems, technicians can ensure that they operate at optimum capacity. This not only helps to prevent flooding and water damage but also minimizes the risk of environmental pollution caused by system failures.

Moreover, preventative maintenance contributes to the overall sustainability of stormwater management. By keeping the infrastructure in good working condition, technicians can reduce the need for resource-intensive repairs or replacements. This conserves materials and reduces the carbon footprint associated with stormwater maintenance.

Key Benefits of Regular Maintenance

Regular maintenance offers numerous benefits to technicians in the stormwater industry. Firstly, it helps to extend the lifespan of stormwater infrastructure and reduces the need for premature replacements. This saves significant costs for both maintenance organizations and customers.

Additionally, through regular maintenance, technicians can improve the efficiency of stormwater systems, leading to reduced energy consumption. By optimizing pump performance, minimizing leaks, and ensuring proper drainage, technicians can help clients save on energy bills and reduce their environmental impact.

Maintenance activities also provide an opportunity for technicians to identify and implement necessary upgrades or modifications to stormwater systems. This ensures that the infrastructure remains up-to-date and capable of handling changing weather patterns and increasing demands.

Furthermore, regular maintenance helps to build trust and confidence among stakeholders. By demonstrating a commitment to proactive maintenance, maintenance organizations can enhance their reputation and attract new clients. This can lead to increased business opportunities and long-term partnerships.

In conclusion, preventative maintenance is a vital aspect of stormwater management. By proactively addressing issues, ensuring the safety and functionality of infrastructure, and reaping the benefits of regular maintenance, technicians can contribute to the efficient and sustainable management of stormwater systems.

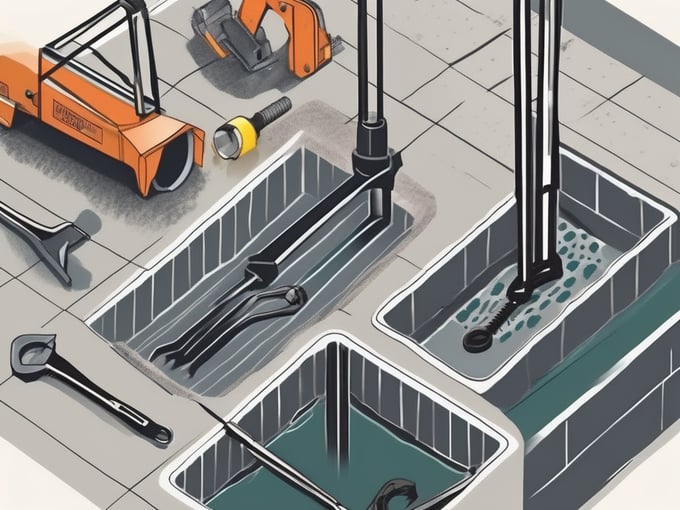

Essential Tools and Equipment for Preventative Maintenance

Technicians performing preventative maintenance in the stormwater industry require the appropriate tools and equipment for effective and safe operations. Without these essential items, maintaining stormwater systems would be challenging and potentially dangerous.

Safety Gear for Technicians

Personal Protective Equipment (PPE) is crucial to ensure the safety of technicians during maintenance tasks. This can include hardhats, safety glasses, safety gloves, high-visibility clothing, and protective footwear. These items are designed to protect technicians from potential hazards such as falling debris, chemical spills, or electrical shocks.

Furthermore, technicians should also have access to emergency equipment such as first aid kits and fire extinguishers. In the event of an accident or injury, having these resources readily available can make a significant difference in the outcome.

Maintenance Tools Every Technician Should Have

Technicians must have a range of tools and equipment to carry out various maintenance tasks effectively. These tools not only enable them to perform their duties efficiently but also contribute to the overall longevity and functionality of stormwater systems.

Some of the essential maintenance tools include wrenches, pliers, screwdrivers, pipe cutters, and pressure gauges. These tools allow technicians to tighten loose fittings, replace damaged components, and measure the pressure within the system. By having these tools on hand, technicians can quickly address any issues that may arise during maintenance.

Depending on the specific requirements of the stormwater system, specialized equipment such as drain snakes or CCTV cameras may also be necessary. Drain snakes are used to remove blockages within pipes, ensuring the smooth flow of water. CCTV cameras, on the other hand, provide technicians with a visual inspection of the system's interior, allowing them to identify any potential problems or areas in need of repair.

It is important for technicians to regularly inspect and maintain stormwater systems to prevent costly and disruptive issues from occurring. By having the right tools and equipment at their disposal, technicians can efficiently carry out preventative maintenance tasks, ensuring the optimal performance and longevity of stormwater systems.

Comprehensive Checklist for Preventative Maintenance

Having a comprehensive checklist for preventative maintenance ensures that technicians cover all necessary tasks systematically and consistently. This checklist can be customized for specific stormwater systems, but generally includes daily, weekly, monthly, and annual tasks.

Preventative maintenance is crucial for keeping stormwater systems in optimal condition. By regularly inspecting and maintaining these systems, potential issues can be identified and resolved before they escalate into major problems. Let's take a closer look at the different tasks that should be included in a comprehensive preventative maintenance checklist.

Daily Maintenance Tasks

On a daily basis, technicians should inspect stormwater infrastructure for any visible signs of damage or blockages. This includes visually checking drains, culverts, and catch basins to ensure they are clear from debris. By promptly removing any obstructions, the risk of flooding or overflow during heavy rain events can be minimized.

In addition to inspecting the physical components of the stormwater system, technicians should also monitor water levels and flow rates to identify any abnormalities. Sudden changes in water levels or unusual flow patterns may indicate a potential issue, such as a clogged pipe or a malfunctioning pump. By detecting these problems early on, appropriate actions can be taken to prevent further damage.

Weekly and Monthly Maintenance Tasks

Weekly and monthly tasks involve performing deeper inspections and cleanings to ensure the long-term functionality of the stormwater system. One important task is using Closed-Circuit Television (CCTV) cameras to inspect pipes for cracks or blockages. This advanced technology allows technicians to visually assess the condition of the pipes without the need for costly and time-consuming excavations. By identifying any structural issues or obstructions, necessary repairs or cleanings can be scheduled promptly.

Clearing debris from stormwater collection points is another crucial task that should be performed regularly. Accumulated debris, such as leaves, branches, and trash, can obstruct the flow of stormwater, leading to backups and potential flooding. Technicians should remove this debris using appropriate tools and dispose of it properly.

Checking the performance of pumps or valves is also an essential part of preventative maintenance. These mechanical components play a crucial role in managing stormwater flow and preventing flooding. Technicians should ensure that pumps are operating smoothly and efficiently, and valves are functioning correctly. Routine maintenance, such as lubricating moving parts as necessary, should be performed to prolong the lifespan of these critical components.

By following a comprehensive checklist for preventative maintenance, stormwater systems can be effectively managed and potential issues can be addressed in a timely manner. Regular inspections, cleanings, and maintenance tasks are essential for ensuring the longevity and functionality of these crucial infrastructure systems.

Common Challenges in Preventative Maintenance and How to Overcome Them

Although preventative maintenance offers numerous benefits, technicians may encounter challenges along the way. By being aware of these challenges and implementing suitable strategies, technicians can ensure the success of their maintenance efforts.

Preventative maintenance plays a crucial role in keeping equipment and machinery in optimal condition, reducing the risk of unexpected breakdowns, and extending their lifespan. However, there are several challenges that technicians may face in their pursuit of effective maintenance practices. Let's explore some of these challenges in more detail and discuss strategies to overcome them.

Dealing with Equipment Failure

Even with regular maintenance, equipment failures may occur. It is crucial for technicians to have contingency plans in place to minimize downtime and mitigate the impact of failures. This can involve having spare parts readily available, establishing maintenance teams for emergencies, and implementing robust communication and reporting systems.

When equipment fails unexpectedly, it can disrupt operations and lead to significant financial losses. To address this challenge, technicians should maintain a well-stocked inventory of spare parts that are frequently required for repairs. This ensures that they can quickly replace faulty components and minimize downtime.

In addition to having spare parts, establishing dedicated maintenance teams for emergencies is essential. These teams should be trained and equipped to handle urgent repairs, allowing them to respond promptly and efficiently to unexpected breakdowns.

Furthermore, implementing robust communication and reporting systems can help technicians stay informed about equipment failures and coordinate their efforts effectively. By utilizing digital tools and software, technicians can streamline the process of reporting and tracking maintenance issues, ensuring that all relevant information is readily available to the maintenance teams.

Managing Maintenance Schedules

With numerous maintenance tasks to handle, technicians must effectively manage their schedules to ensure all necessary activities are completed on time. This requires effective planning, organization, and coordination among team members. Utilizing digital tools and software can help streamline the scheduling process and ensure accountability.

Maintaining a comprehensive maintenance schedule is crucial for technicians to stay on top of their tasks and prevent any essential maintenance activities from being overlooked. To effectively manage their schedules, technicians should prioritize tasks based on their urgency and impact on operations.

Utilizing digital tools and software can greatly assist in streamlining the scheduling process. These tools can provide technicians with a centralized platform to create and manage maintenance schedules, assign tasks to team members, and track progress. Additionally, they can send automated reminders and notifications to ensure that all maintenance activities are completed on time.

Furthermore, effective coordination among team members is essential for successful maintenance scheduling. Technicians should communicate regularly, share updates, and collaborate to ensure that all tasks are completed efficiently and within the designated timeframes.

By understanding and addressing these common challenges, technicians can enhance the effectiveness of their preventative maintenance efforts. With proper planning, coordination, and the utilization of digital tools, technicians can overcome these challenges and ensure the smooth operation of equipment and machinery.

Best Practices for Preventative Maintenance in the Stormwater Industry

To optimize preventative maintenance efforts in the stormwater industry, following best practices is essential. By implementing these practices, technicians can ensure the longevity and efficiency of stormwater systems, minimizing the risk of costly repairs and environmental damage.

Implementing a Maintenance Plan

Having a well-defined maintenance plan is crucial for technicians to streamline their activities and ensure consistency. This plan should outline the frequency and scope of maintenance tasks and provide guidelines for documentation and reporting. By establishing a clear roadmap for maintenance activities, technicians can effectively prioritize tasks and allocate resources.

Regular evaluation and improvement of the plan can help adapt to changing needs and technologies. As stormwater systems evolve, it is important to reassess the maintenance plan periodically to incorporate new industry standards and advancements. This proactive approach ensures that maintenance efforts remain effective and up-to-date.

Training and Skill Development for Technicians

Continuous training and skill development are essential for technicians to stay updated with the latest practices and technologies in the stormwater industry. Regular training sessions and workshops can enhance their knowledge and expertise, enabling them to perform maintenance tasks effectively and safely.

Technicians should receive training on various aspects of stormwater systems, including inspection techniques, equipment operation, and maintenance procedures. This comprehensive training equips them with the necessary skills to identify potential issues, troubleshoot problems, and implement appropriate preventative measures.

Furthermore, ongoing skill development programs can help technicians stay abreast of emerging trends and technologies in the stormwater industry. By attending conferences, seminars, and industry events, technicians can network with experts and gain valuable insights into innovative maintenance practices.

By investing in training and skill development, organizations can create a knowledgeable and competent workforce that is capable of efficiently maintaining stormwater systems. This not only improves the overall performance of the systems but also enhances the safety and reliability of the entire infrastructure.

Future Trends in Preventative Maintenance

The field of preventative maintenance is constantly evolving, driven by advancements in technology and increased focus on sustainability. In order to stay ahead of the curve, it is important for technicians and industry professionals to be aware of the latest trends and developments in this field.

Technological Advancements in Maintenance

New technologies such as Internet of Things (IoT) sensors, data analytics, and predictive maintenance algorithms are revolutionizing preventative maintenance. These technologies enable real-time monitoring, early fault detection, and more efficient decision-making, optimizing maintenance efforts and reducing costs.

For example, IoT sensors can be installed in stormwater infrastructure to collect data on various parameters such as water flow, water quality, and structural integrity. This data can then be analyzed using advanced algorithms to identify potential issues before they become major problems. This proactive approach allows technicians to schedule maintenance activities in a more strategic manner, minimizing downtime and maximizing the lifespan of the infrastructure.

Furthermore, data analytics can provide valuable insights into the performance of stormwater systems. By analyzing historical data, technicians can identify patterns and trends, enabling them to make data-driven decisions regarding maintenance activities. This not only improves the efficiency of maintenance efforts but also helps in identifying areas where improvements can be made to enhance the overall performance of the system.

Sustainability in Preventative Maintenance

As sustainability becomes a priority, preventative maintenance practices are also evolving to minimize environmental impact. This includes the use of eco-friendly cleaning agents, adoption of green infrastructure practices, and consideration of lifecycle assessments in maintenance decision-making.

One important aspect of sustainable maintenance is the use of eco-friendly cleaning agents. Traditional cleaning agents often contain harmful chemicals that can have a negative impact on the environment. By switching to environmentally friendly alternatives, technicians can ensure that their maintenance activities do not contribute to pollution or harm the surrounding ecosystem.

In addition, the adoption of green infrastructure practices can play a significant role in sustainable preventative maintenance. Green infrastructure refers to the use of natural systems, such as rain gardens and bioswales, to manage stormwater runoff. By incorporating these practices into maintenance activities, technicians can not only improve the performance of the stormwater system but also enhance the overall ecological value of the surrounding area.

Furthermore, considering lifecycle assessments in maintenance decision-making can help in identifying opportunities for improvement and optimization. By evaluating the environmental impact of different maintenance strategies and materials, technicians can make informed decisions that align with sustainability goals. This holistic approach ensures that maintenance activities not only address immediate issues but also contribute to the long-term sustainability of the stormwater infrastructure.

By embracing these emerging trends, technicians can enhance their preventative maintenance practices and contribute to a more sustainable stormwater industry. However, it is important to note that staying up to date with the latest advancements and best practices requires continuous learning and professional development. Technicians should actively seek opportunities to expand their knowledge and skills in order to effectively implement these future trends in their maintenance efforts.

In conclusion, preventative maintenance is a crucial aspect of the stormwater industry. By understanding its importance, acquiring the necessary tools and equipment, following comprehensive checklists, and implementing best practices, technicians can ensure the longevity and efficiency of stormwater infrastructure. Overcoming common challenges and embracing future trends will further enhance maintenance efforts, leading to a more sustainable and resilient stormwater industry.