Important Trends in Data Analytics for Maintenance Technicians in the Water Industry

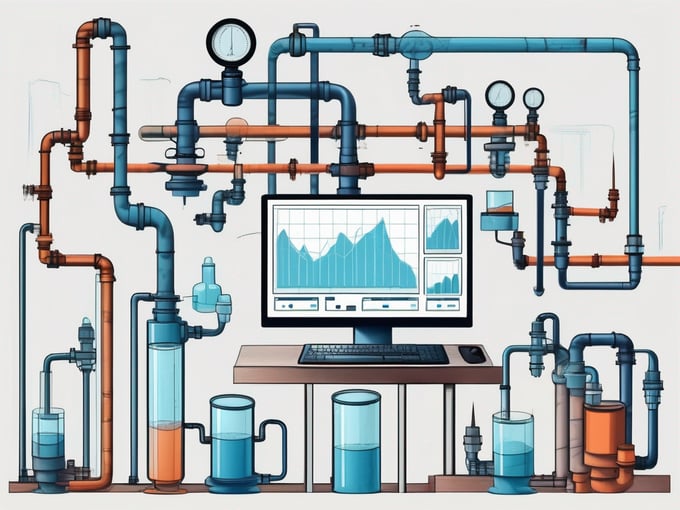

In today's rapidly evolving world, data analytics has become a crucial tool for various industries. In the water industry, maintenance technicians play a vital role in ensuring the efficient operation and quality of water systems. By harnessing the power of data analytics, these technicians can enhance their decision-making process, optimize maintenance routines, and contribute to the overall effectiveness of the water industry. This article aims to provide a comprehensive guide to data analytics specifically tailored for maintenance technicians in the water industry.

Understanding the Importance of Data Analytics in the Water Industry

Data analytics has emerged as a game-changer in the water industry. By analyzing vast amounts of data, maintenance technicians can gain valuable insights into various aspects of water systems, such as water quality, efficiency, and performance. These insights enable technicians to make data-driven decisions, identify potential issues, and proactively address them, ultimately leading to improved maintenance practices and enhanced overall performance.

In today's rapidly evolving world, the water industry faces numerous challenges, including population growth, climate change, and aging infrastructure. These challenges necessitate the adoption of innovative solutions to ensure the sustainable management of water resources. Data analytics provides a powerful tool for water industry professionals to navigate these challenges effectively.

The Role of Maintenance Technicians in Data Analytics

Maintenance technicians play a crucial role in the data analytics process. They collect, analyze, and interpret data to identify patterns, trends, and anomalies that facilitate informed decision-making. By leveraging their technical expertise and industry knowledge, maintenance technicians can translate data into actionable insights that drive maintenance strategies. Furthermore, their hands-on experience enables them to identify data points that are most critical for ensuring optimal system performance and reliability.

These technicians are at the forefront of data collection efforts, utilizing advanced monitoring systems, sensors, and data loggers to gather real-time information about water systems. They meticulously analyze this data, looking for any deviations or irregularities that may indicate potential issues. By identifying these issues early on, maintenance technicians can take proactive measures to prevent system failures, reduce downtime, and minimize the impact on water supply.

The Impact of Data Analytics on Water Quality and Efficiency

One of the significant benefits of data analytics in the water industry is its impact on water quality and efficiency. By continuously monitoring and analyzing key performance indicators, maintenance technicians can quickly identify deviations from expected levels and take immediate corrective actions. They can pinpoint potential sources of contamination, detect leaks, and optimize system functioning to ensure water quality meets regulatory standards.

Water quality is a critical concern for both public health and environmental sustainability. Through data analytics, maintenance technicians can identify trends and patterns in water quality data, enabling them to make informed decisions about treatment processes and ensure the delivery of safe and clean drinking water to communities. By monitoring parameters such as pH levels, turbidity, and disinfection byproducts, technicians can detect any variations that may indicate potential risks to public health.

Moreover, analytics-driven maintenance enables proactive identification of inefficiencies, leading to optimized resource usage, reduced energy consumption, and cost savings. By analyzing data on water consumption, flow rates, and energy usage, maintenance technicians can identify areas where improvements can be made to enhance efficiency. This includes optimizing pump schedules, identifying opportunities for water reuse, and implementing demand management strategies to reduce wastage.

Overall, data analytics has revolutionized the water industry by providing valuable insights and enabling proactive decision-making. It empowers maintenance technicians to optimize system performance, ensure water quality, and enhance overall efficiency. As the industry continues to evolve, data analytics will play an increasingly vital role in addressing the complex challenges faced by the water sector.

Key Concepts in Data Analytics for Maintenance Technicians

Before diving into the practical aspects of data analytics, it is essential to grasp some fundamental concepts that underpin this field.

Data analytics has revolutionized the maintenance industry, empowering technicians to make informed decisions based on data-driven insights. By harnessing the power of advanced technologies and statistical techniques, maintenance technicians can optimize maintenance schedules, minimize downtime, and maximize equipment lifespan.

Introduction to Predictive Maintenance

Predictive maintenance harnesses the power of data analytics to anticipate equipment failures and perform maintenance actions proactively. By continuously monitoring equipment parameters and collecting relevant data, maintenance technicians can create predictive models that forecast potential issues before they occur. This approach minimizes downtime, maximizes equipment lifespan, and optimizes maintenance schedules, resulting in increased system reliability and cost savings.

Imagine a scenario where a maintenance technician receives an alert indicating abnormal vibrations in a critical machine. With predictive maintenance, the technician can analyze historical data, identify patterns, and determine the root cause of the issue. By addressing the problem before it escalates, the technician prevents costly breakdowns and ensures uninterrupted operations.

Understanding Data Mining and Its Relevance

Data mining involves extracting meaningful information and patterns from large datasets. Maintenance technicians can leverage data mining techniques to uncover hidden insights within their maintenance records, sensor data, and other relevant sources. By discovering correlations and relationships between various data points, technicians can identify factors that contribute to specific failures or inefficiencies. This knowledge enables them to prioritize maintenance tasks, optimize resource allocation, and ensure effective risk management.

For example, by analyzing maintenance records and sensor data, technicians can identify recurring patterns that indicate potential equipment failures. They can then take proactive measures such as adjusting maintenance schedules, replacing worn-out components, or implementing preventive measures to mitigate risks. Data mining empowers technicians to make data-driven decisions that optimize maintenance operations and enhance overall equipment performance.

The Importance of Data Visualization in Maintenance

Data visualization plays a crucial role in enhancing maintenance technicians' understanding of complex datasets. By representing data visually through charts, graphs, and diagrams, maintenance technicians can quickly grasp patterns, trends, and outliers. Visualization also enables technicians to communicate their findings effectively and gain insights from non-technical stakeholders. This collaborative approach enhances decision-making processes and fosters a data-driven culture within the maintenance team.

Consider a scenario where a maintenance technician needs to present the findings of a comprehensive equipment performance analysis to the management team. By using data visualization techniques, the technician can create visually appealing and easy-to-understand charts and graphs that highlight key performance metrics, trends, and areas of improvement. This visual representation enables the management team to make informed decisions and allocate resources effectively, ultimately leading to improved maintenance strategies and operational efficiency.

In conclusion, data analytics is a powerful tool that empowers maintenance technicians to optimize maintenance operations, prevent equipment failures, and enhance overall system reliability. By understanding key concepts such as predictive maintenance, data mining, and data visualization, technicians can unlock the full potential of data analytics and drive continuous improvement in the maintenance industry.

Tools and Techniques for Data Analytics in the Water Industry

To successfully implement data analytics in the water industry, maintenance technicians need access to appropriate tools and techniques. With the advancement of technology, several tools and techniques have emerged that enable technicians to gather accurate and reliable information about various aspects of water systems, such as flow rates, pressure levels, and water quality parameters. Let's explore some of these tools and techniques in detail.

Overview of Data Collection Tools

Data collection tools play a crucial role in capturing real-time data from sensors, meters, and other monitoring devices. These tools enable maintenance technicians to gather accurate and reliable information about various aspects of water systems. For instance, flow meters provide real-time data on the flow rates of water in pipelines, helping technicians monitor the efficiency of water distribution. Similarly, pressure sensors measure the pressure levels in water systems, allowing technicians to identify potential issues such as leaks or blockages. Additionally, water quality sensors provide information about parameters like pH levels, turbidity, and chemical composition, helping technicians ensure the safety and quality of the water supply.

The collected data serves as the foundation for meaningful analytics-driven insights and decision-making. By analyzing this data, maintenance technicians can identify patterns, trends, and anomalies, enabling them to make data-driven decisions regarding maintenance, repairs, and system optimization.

Data Analysis Techniques for Maintenance Technicians

Maintenance technicians can employ a variety of data analysis techniques to extract valuable insights from the collected data. These techniques enable technicians to make informed decisions and take proactive measures to ensure the smooth operation of water systems. Let's explore some of these techniques:

- Descriptive Analytics: Descriptive analytics provides a summary of historic data, highlighting trends, and patterns. By analyzing past data, maintenance technicians can gain a better understanding of system behavior and identify recurring issues. For example, they can identify peak demand periods or detect patterns of water quality degradation.

- Diagnostic Analytics: Diagnostic analytics helps technicians identify the root causes of failures and inefficiencies. By analyzing data and applying statistical techniques, technicians can pinpoint the factors contributing to system failures or suboptimal performance. This enables them to address the underlying issues and implement corrective measures effectively.

- Predictive Analytics: Predictive analytics enables technicians to forecast equipment failures and plan preventive maintenance activities. By analyzing historical data and utilizing machine learning algorithms, technicians can predict when equipment is likely to fail or require maintenance. This proactive approach helps minimize downtime, reduce costs, and optimize maintenance schedules.

- Prescriptive Analytics: Prescriptive analytics suggests optimal maintenance strategies based on historical data and industry best practices. By combining historical data with domain expertise, technicians can make data-driven decisions regarding maintenance activities. This approach helps optimize resource allocation, improve system performance, and extend the lifespan of equipment.

Software Solutions for Data Analytics in the Water Industry

Various software solutions are specifically designed to facilitate data analytics in the water industry. These solutions offer features such as data visualization, predictive modeling, data mining, and reporting capabilities. By utilizing these tools, maintenance technicians can streamline their data analysis processes, improve efficiency, and access advanced analytics functionalities that enhance their decision-making abilities.

Data visualization tools allow technicians to represent complex data sets in a visually appealing and easy-to-understand manner. This helps them identify patterns, trends, and anomalies more effectively. Predictive modeling tools enable technicians to build models that can predict future outcomes based on historical data. These models can be used to forecast water demand, identify potential system failures, or optimize maintenance schedules. Data mining tools help technicians discover hidden patterns and relationships within large datasets, providing valuable insights for system optimization and performance improvement. Reporting capabilities allow technicians to generate comprehensive reports and share insights with stakeholders, facilitating effective communication and collaboration.

By leveraging these software solutions, maintenance technicians can harness the power of data analytics to make informed decisions, optimize system performance, and ensure the efficient and sustainable operation of water systems.

Implementing Data Analytics in Your Maintenance Routine

Integrating data analytics into the maintenance routine can be a transformative process. It requires careful planning, coordination, and a thorough understanding of the implementation steps.

By incorporating data analytics into maintenance practices, organizations can unlock valuable insights and optimize their maintenance activities. This can lead to improved equipment uptime, reduced costs, and enhanced overall operational efficiency.

Steps to Integrate Data Analytics in Maintenance

The first step in implementing data analytics is defining clear objectives and identifying key performance indicators (KPIs) that align with these objectives. This ensures that the analytics efforts are focused and aligned with the organization's goals.

Next, technicians need to ensure data quality and consistency by validating and cleansing the collected data. This involves removing any outliers or errors that may skew the analysis results. By ensuring data accuracy, organizations can have confidence in the insights generated through analytics.

Once the data is ready, technicians can explore different analysis techniques and approaches to uncover valuable insights. This may involve using statistical models, machine learning algorithms, or data visualization tools to identify patterns, trends, and anomalies in the data. By leveraging advanced analytics techniques, organizations can gain a deeper understanding of their maintenance operations.

Finally, technicians need to translate these insights into actionable maintenance strategies, measure performance, and continuously refine their analytics processes. This involves using the insights generated through analytics to make data-driven decisions about maintenance activities. By regularly evaluating the effectiveness of these strategies and making adjustments as needed, organizations can continuously improve their maintenance practices.

Overcoming Challenges in Implementing Data Analytics

While data analytics offers significant benefits, implementing it comes with its fair share of challenges. These challenges may include data security and privacy concerns, data integration issues, skill gaps within the maintenance team, and resistance to change.

Data security and privacy concerns are paramount when working with sensitive maintenance data. Organizations must ensure that appropriate security measures are in place to protect the data from unauthorized access or breaches.

Data integration can be a complex task, especially when dealing with multiple data sources and formats. Organizations need to establish robust data integration processes to ensure that data from various systems can be effectively combined and analyzed.

Skill gaps within the maintenance team can hinder the successful implementation of data analytics. Organizations should invest in training and upskilling their technicians to ensure they have the necessary knowledge and expertise to leverage data analytics effectively.

Resistance to change is another common challenge when implementing data analytics. It is important to communicate the benefits of data analytics to all stakeholders and involve them in the process. By fostering a culture of data-driven decision-making, organizations can overcome resistance and drive successful implementation.

Measuring the Success of Your Data Analytics Implementation

Measuring the success of a data analytics implementation is crucial for assessing its impact and continuously improving the maintenance practices. Key metrics to consider include equipment uptime, mean time between failures, response time to maintenance requests, and cost savings achieved through optimized maintenance activities.

Regularly monitoring and analyzing these metrics allow organizations to identify areas for improvement and make data-driven decisions to enhance maintenance operations. By leveraging data analytics, organizations can proactively identify potential issues, optimize maintenance schedules, and allocate resources more effectively.

In conclusion, integrating data analytics into the maintenance routine can bring significant benefits to organizations. By following the steps outlined above and addressing the challenges that may arise, organizations can harness the power of data analytics to optimize their maintenance practices and drive operational excellence.

Future Trends in Data Analytics for the Water Industry

The water industry is continually evolving, and data analytics plays a pivotal role in shaping its future.

The Role of Artificial Intelligence in Maintenance

Artificial intelligence (AI) has the potential to revolutionize maintenance practices in the water industry. By leveraging machine learning algorithms, AI can automatically analyze vast amounts of data, detect anomalies, and recommend maintenance actions. This proactive approach enhances system reliability, reduces unplanned downtime, and optimizes resource utilization.

Predictive Analytics and the Future of Maintenance

Predictive analytics is expected to become even more powerful in the future, with advancements in machine learning and artificial intelligence. Maintenance technicians will be able to deploy predictive models with higher accuracy and improved forecasting capabilities. This will enable them to take preemptive maintenance actions, further reducing downtime and driving continuous improvement in water system performance.

The Impact of Big Data on the Water Industry

As the amount of data generated by water systems continues to grow exponentially, the concept of big data becomes increasingly relevant. Big data analytics allows maintenance technicians to process and analyze massive datasets in near real-time, uncovering patterns and insights that were previously unattainable. This enables organizations to make more informed decisions, optimize maintenance strategies, and enhance overall water system operations.

By embracing data analytics, maintenance technicians in the water industry can unlock a world of possibilities. From improving water quality and efficiency to embracing future trends, the potential for data analytics to drive transformative change is immense. With the guidance provided in this ultimate guide, maintenance technicians are well-equipped to embark on their data analytics journey and contribute to the advancement of the water industry.