Understanding Dew Point Sensors: How They Work and Their Applications

Dew point sensors are critical devices used in various industries to measure the moisture content in the air. Understanding how these sensors work and their diverse applications can provide valuable insights into their importance in maintaining optimal environmental conditions. This article delves into the operational mechanics of dew point sensors, their types, and their applications across different sectors.

What is Dew Point?

The dew point is the temperature at which air becomes saturated with moisture and water vapor begins to condense into liquid. This phenomenon occurs when the air temperature drops, leading to increased humidity levels. Understanding dew point is essential for various applications, including HVAC systems, meteorology, and industrial processes. For instance, in meteorology, the dew point is a critical indicator of atmospheric moisture, often used to predict weather patterns and the likelihood of precipitation. A higher dew point typically suggests a more humid atmosphere, which can lead to the formation of clouds and storms.

The Importance of Dew Point Measurement

Measuring dew point is crucial for maintaining comfort and safety in indoor environments. In HVAC systems, for instance, controlling humidity levels can prevent mold growth and enhance air quality. High humidity levels can lead to discomfort and health issues, making it vital for HVAC professionals to monitor dew point closely. In industrial settings, monitoring dew point helps in preventing equipment corrosion and ensuring product quality. For example, in the manufacturing of electronics, maintaining a specific dew point is essential to avoid moisture-related defects that could compromise the integrity of the products.

Factors Influencing Dew Point

Several factors can influence the dew point, including temperature, pressure, and humidity levels. Higher temperatures generally lead to higher dew points, indicating a greater moisture content in the air. Conversely, lower temperatures result in lower dew points. Understanding these factors is essential for accurate measurements and applications. Additionally, geographical location plays a significant role; coastal areas often experience higher dew points due to the proximity of large bodies of water, while arid regions typically have lower dew points. Seasonal changes can also affect dew point, with warmer months usually exhibiting higher dew points, which can impact everything from agriculture to energy consumption patterns.

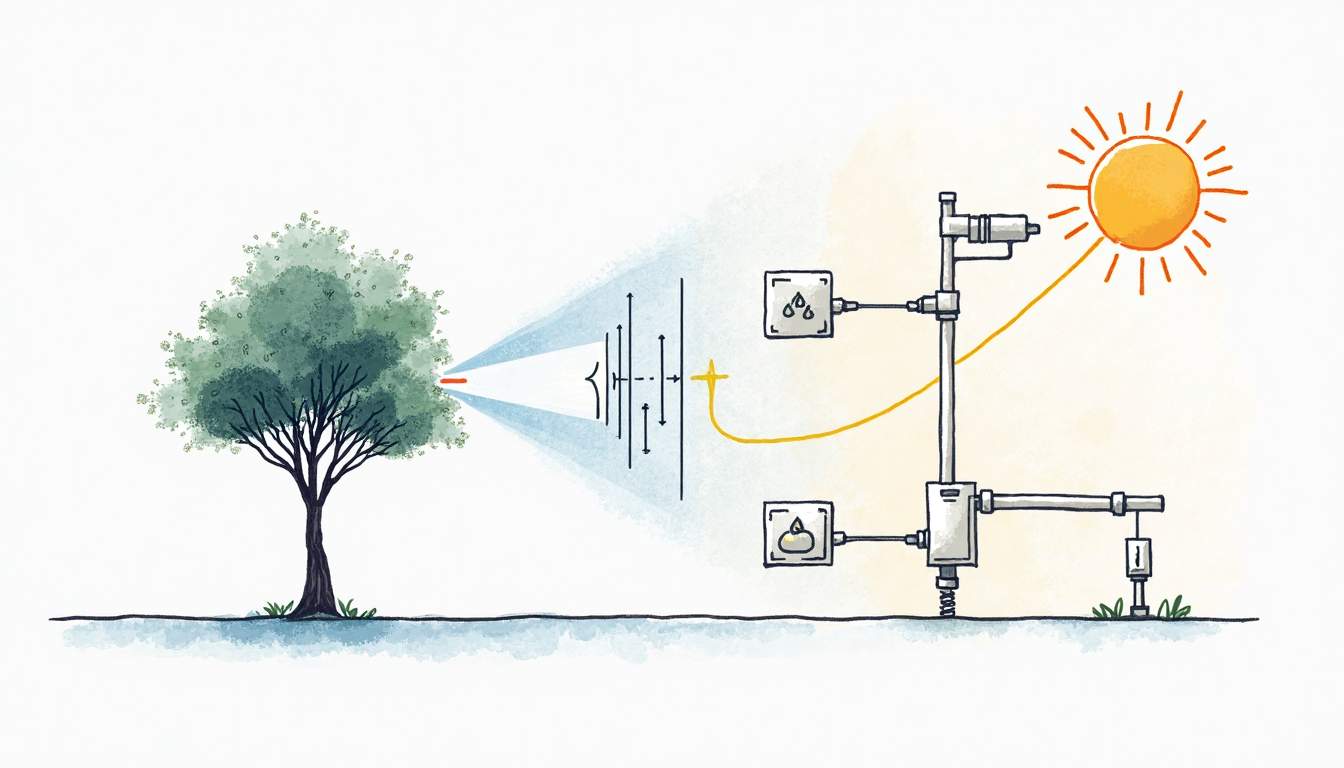

How Dew Point Sensors Work

Dew point sensors operate based on various principles to measure the moisture content in the air accurately. These sensors typically utilize either capacitive, resistive, or chilled mirror technologies to determine dew point levels. Understanding how these sensors function is crucial for applications in meteorology, HVAC systems, and industrial processes, where precise humidity control is essential.

Capacitive Dew Point Sensors

Capacitive dew point sensors work by measuring changes in capacitance that occur as humidity levels change. These sensors contain a hygroscopic dielectric material that absorbs moisture. As the moisture content increases, the dielectric constant changes, allowing the sensor to calculate the dew point accurately. Capacitive sensors are known for their fast response times and high accuracy, making them suitable for various applications. They are often used in environments where rapid fluctuations in humidity occur, such as in greenhouses or climate-controlled storage facilities. Additionally, advancements in materials science have led to the development of more sensitive capacitive sensors, enabling even finer measurements in challenging conditions.

Resistive Dew Point Sensors

Resistive dew point sensors operate on the principle of measuring changes in resistance caused by humidity variations. These sensors typically use a thin film of hygroscopic material that alters its resistance based on the moisture content in the air. While resistive sensors are generally less expensive, they may not offer the same level of accuracy and response time as capacitive sensors. However, they are still widely used in applications where cost is a significant factor, such as in residential HVAC systems or basic weather stations. Furthermore, ongoing innovations in resistive technology are improving their performance, making them more competitive in terms of accuracy and reliability.

Chilled Mirror Dew Point Sensors

Chilled mirror dew point sensors are considered the gold standard for dew point measurement. These sensors work by cooling a mirror until condensation forms on its surface. The temperature at which condensation occurs is the dew point. This method is highly accurate and reliable, making it ideal for critical applications such as laboratories and calibration standards. Chilled mirror sensors are often employed in industrial processes where precise humidity control is vital, such as in pharmaceutical manufacturing and food processing. Additionally, these sensors can provide real-time data, allowing for immediate adjustments to be made in environmental controls, thereby enhancing product quality and safety.

Types of Dew Point Sensors

Dew point sensors come in various types, each designed for specific applications and environments. Understanding the different types can help in selecting the right sensor for a given application.

Portable Dew Point Sensors

Portable dew point sensors are compact and designed for field measurements. They are often battery-operated and easy to transport, making them ideal for HVAC technicians and environmental monitoring. These sensors provide quick and accurate readings, allowing for immediate analysis and decision-making. Their versatility also enables users to conduct spot checks in various locations, ensuring that moisture levels are maintained within acceptable limits. This is particularly crucial in industries where humidity control is vital, such as food processing and pharmaceuticals, where deviations can lead to spoilage or contamination.

Fixed Dew Point Sensors

Fixed dew point sensors are installed in a specific location and continuously monitor the dew point in that area. These sensors are commonly used in industrial settings, HVAC systems, and laboratories. They provide real-time data and can be integrated into larger monitoring systems for enhanced control and efficiency. The continuous data stream allows for proactive maintenance and can help prevent issues such as condensation, which can lead to equipment damage or reduced product quality. Furthermore, many fixed sensors come equipped with advanced features such as alarm systems that notify operators when dew point levels exceed predetermined thresholds, ensuring that corrective actions can be taken swiftly.

Wireless Dew Point Sensors

Wireless dew point sensors offer the advantage of remote monitoring and data collection. These sensors use wireless communication technologies to transmit data to a central system, allowing for real-time analysis without the need for physical connections. This feature is particularly beneficial in hard-to-reach locations or where wiring is impractical. Additionally, wireless sensors often come with cloud connectivity, enabling users to access data from anywhere via smartphones or computers. This capability is especially useful for facilities managers who need to monitor multiple sites simultaneously, providing them with the flexibility to respond to changing conditions promptly. Moreover, the integration of wireless sensors with IoT (Internet of Things) platforms can enhance predictive maintenance strategies, leading to improved operational efficiency and reduced downtime.

Applications of Dew Point Sensors

Dew point sensors find applications across various industries, each benefiting from accurate humidity measurements. Here are some of the key sectors where these sensors play a vital role.

HVAC Systems

In HVAC systems, dew point sensors help maintain optimal humidity levels, ensuring comfort and air quality. By monitoring the dew point, HVAC systems can adjust cooling and heating processes to prevent condensation, mold growth, and energy inefficiencies. This is particularly crucial in commercial buildings, where large numbers of occupants can significantly impact indoor air quality. Moreover, the integration of dew point sensors with smart building technologies allows for real-time data analysis, enabling predictive maintenance and energy savings. This not only enhances occupant comfort but also reduces operational costs, making it a win-win for facility managers.

Industrial Processes

Many industrial processes require precise humidity control to ensure product quality and equipment longevity. Dew point sensors are used in manufacturing, food processing, and pharmaceuticals to monitor moisture levels. For instance, in food processing, maintaining the right humidity can prevent spoilage and ensure product safety. Additionally, in the pharmaceutical industry, dew point sensors are critical for maintaining sterile environments, where even slight variations in humidity can compromise the integrity of sensitive compounds. The ability to continuously monitor and adjust humidity levels helps manufacturers comply with stringent regulatory standards, ultimately safeguarding both their products and their reputations.

Weather Monitoring

Dew point sensors are essential tools in meteorology for predicting weather patterns. By measuring the dew point, meteorologists can assess humidity levels and forecast conditions such as fog, frost, and precipitation. Accurate dew point measurements contribute to more reliable weather predictions, benefiting agriculture, aviation, and outdoor events. Furthermore, these sensors are increasingly being deployed in remote and challenging environments, such as mountainous regions or arid deserts, where traditional weather stations may be scarce. This expanded deployment enhances the granularity of weather data, allowing for localized forecasts that can better inform farmers about irrigation needs or help pilots make informed decisions regarding flight safety.

Benefits of Using Dew Point Sensors

Utilizing dew point sensors offers numerous benefits across various applications. Understanding these advantages can help organizations make informed decisions about their humidity monitoring needs.

Enhanced Accuracy

Dew point sensors provide accurate measurements of moisture content, which is crucial for applications requiring precise humidity control. This accuracy helps prevent issues such as condensation, mold growth, and equipment damage, ultimately saving costs and ensuring product quality. For instance, in food storage and processing facilities, maintaining the right dew point is essential to preserve freshness and prevent spoilage. With accurate data from dew point sensors, managers can adjust environmental conditions in real-time, safeguarding both the integrity of their products and the satisfaction of their customers.

Improved Efficiency

By continuously monitoring dew point levels, organizations can optimize their processes and systems. For example, in HVAC systems, accurate dew point measurements enable more efficient cooling and heating operations, reducing energy consumption and operational costs. Furthermore, industries such as pharmaceuticals and electronics manufacturing rely on controlled environments to maintain product quality. By integrating dew point sensors into their systems, these industries can ensure that humidity levels remain within specified ranges, thus enhancing production efficiency and minimizing waste due to defective products.

Proactive Maintenance

Implementing dew point sensors allows for proactive maintenance of equipment and systems. By monitoring humidity levels, organizations can identify potential issues before they escalate, reducing downtime and maintenance costs. This proactive approach enhances overall operational efficiency. For example, in industrial settings, unexpected humidity fluctuations can lead to equipment corrosion or malfunction. By utilizing dew point sensors, maintenance teams can receive alerts when humidity levels approach critical thresholds, allowing them to take corrective actions before any significant damage occurs. This not only extends the lifespan of equipment but also fosters a culture of reliability and safety within the workplace.

Data-Driven Decision Making

In addition to the immediate operational benefits, dew point sensors contribute to data-driven decision-making processes. The data collected from these sensors can be analyzed to identify trends and patterns in humidity levels over time. Organizations can leverage this information to make strategic adjustments to their environments, whether it’s optimizing energy use in climate control systems or refining storage conditions for sensitive materials. Furthermore, this wealth of data can support compliance with industry regulations, as accurate records of humidity control can be crucial for audits and certifications in regulated sectors.

Challenges in Dew Point Measurement

While dew point sensors offer numerous benefits, there are also challenges associated with their use. Understanding these challenges can help organizations mitigate risks and improve measurement accuracy.

Calibration and Drift

One of the primary challenges in dew point measurement is sensor calibration and drift over time. Regular calibration is necessary to ensure accurate readings, especially in critical applications. Organizations must establish a calibration schedule and follow best practices to maintain sensor accuracy. Additionally, the choice of calibration method—whether using a reference sensor or a calibration chamber—can significantly impact the reliability of the results. In environments where precision is paramount, investing in automated calibration systems can further enhance consistency and reduce human error.

Environmental Factors

Environmental factors such as temperature fluctuations, pressure changes, and contaminants can affect dew point measurements. It is essential to consider these factors when selecting and installing dew point sensors to ensure reliable performance in varying conditions. For instance, sensors exposed to high levels of humidity or particulate matter may experience accelerated wear or malfunction. Implementing protective measures, such as filters or enclosures, can help shield sensors from adverse environmental conditions and extend their operational lifespan. Furthermore, understanding the local climate and operational environment can aid in selecting the most suitable sensor technology for specific applications.

Cost Considerations

The initial investment and ongoing maintenance costs of dew point sensors can be a concern for some organizations. While high-quality sensors may come with a higher price tag, the long-term benefits of accuracy and efficiency often outweigh these costs. Organizations must evaluate their specific needs and budget when selecting dew point sensors. It is also worth considering the total cost of ownership, which includes not only the purchase price but also installation, maintenance, and potential downtime due to sensor failure. Some organizations may find that investing in more advanced sensors with built-in diagnostics can reduce overall costs by minimizing troubleshooting time and improving system reliability. Additionally, exploring options for leasing or financing equipment can make high-quality sensors more accessible without straining budgets.

Future Trends in Dew Point Sensing Technology

The field of dew point sensing technology is continuously evolving, driven by advancements in materials, electronics, and data analysis. Staying informed about these trends can help organizations leverage new technologies for improved humidity monitoring.

Integration with IoT

The integration of dew point sensors with the Internet of Things (IoT) is a significant trend shaping the future of humidity monitoring. IoT-enabled sensors can provide real-time data analysis, remote monitoring, and automated control systems, enhancing operational efficiency and decision-making. With the ability to connect to cloud platforms, these sensors can share data across multiple devices, allowing for comprehensive environmental assessments. This connectivity not only facilitates immediate responses to fluctuations in humidity but also enables predictive maintenance, where potential issues can be identified and addressed before they escalate into significant problems.

Smart Sensors

Smart dew point sensors equipped with advanced algorithms can analyze data more effectively, providing insights into trends and patterns. These sensors can adapt to changing conditions, improving measurement accuracy and reliability. The development of smart sensors will likely lead to more sophisticated humidity control systems in the future. Furthermore, the incorporation of machine learning techniques into these sensors can enhance their predictive capabilities, allowing them to learn from historical data and optimize performance accordingly. This evolution will be particularly beneficial in industries such as agriculture, where precise humidity control can directly impact crop yield and quality.

Miniaturization and Portability

As technology advances, the miniaturization of dew point sensors is becoming more prevalent. Smaller, portable sensors will enable more widespread use in various applications, including personal weather stations and mobile monitoring devices. This trend will enhance accessibility and convenience for users. Additionally, the development of battery-powered and energy-efficient sensors will allow for prolonged usage in remote or off-grid locations, making it feasible to monitor humidity levels in areas previously deemed inaccessible. This portability can also foster innovation in consumer products, such as smart home devices that automatically adjust indoor climates based on real-time dew point readings, ensuring optimal comfort and energy efficiency.

Conclusion

Dew point sensors are invaluable tools for measuring humidity levels and ensuring optimal environmental conditions across various industries. Understanding how these sensors work, their applications, and the benefits they offer is essential for organizations looking to improve their humidity monitoring processes. As technology continues to evolve, the future of dew point sensing promises even greater accuracy, efficiency, and integration with advanced systems.