Understanding Pump Alarm Systems: A Comprehensive Guide

Pump alarm systems are essential components in various industries, ensuring the safe and efficient operation of pumps. These systems monitor the performance of pumps, alerting operators to any irregularities that could lead to equipment failure or safety hazards. This comprehensive guide aims to provide a thorough understanding of pump alarm systems, their components, functionalities, and best practices for implementation.

What is a Pump Alarm System?

A pump alarm system is designed to monitor the operational status of pumps and associated equipment. It detects abnormal conditions such as high or low pressure, temperature fluctuations, and flow rate discrepancies. When these conditions arise, the system triggers alarms to notify operators, allowing for immediate corrective actions.

The Importance of Pump Alarm Systems

In industrial settings, pumps play a critical role in processes ranging from water treatment to chemical manufacturing. A malfunctioning pump can lead to significant downtime, costly repairs, and even safety incidents. By implementing a reliable pump alarm system, organizations can minimize these risks, ensuring continuous operation and safeguarding personnel and assets.

Moreover, the integration of pump alarm systems contributes to overall operational efficiency. By providing real-time data and alerts, these systems enable operators to make informed decisions quickly, reducing the likelihood of catastrophic failures. This proactive approach not only enhances the reliability of the pumping systems but also extends their lifespan, ultimately leading to lower maintenance costs and improved resource management.

Key Components of a Pump Alarm System

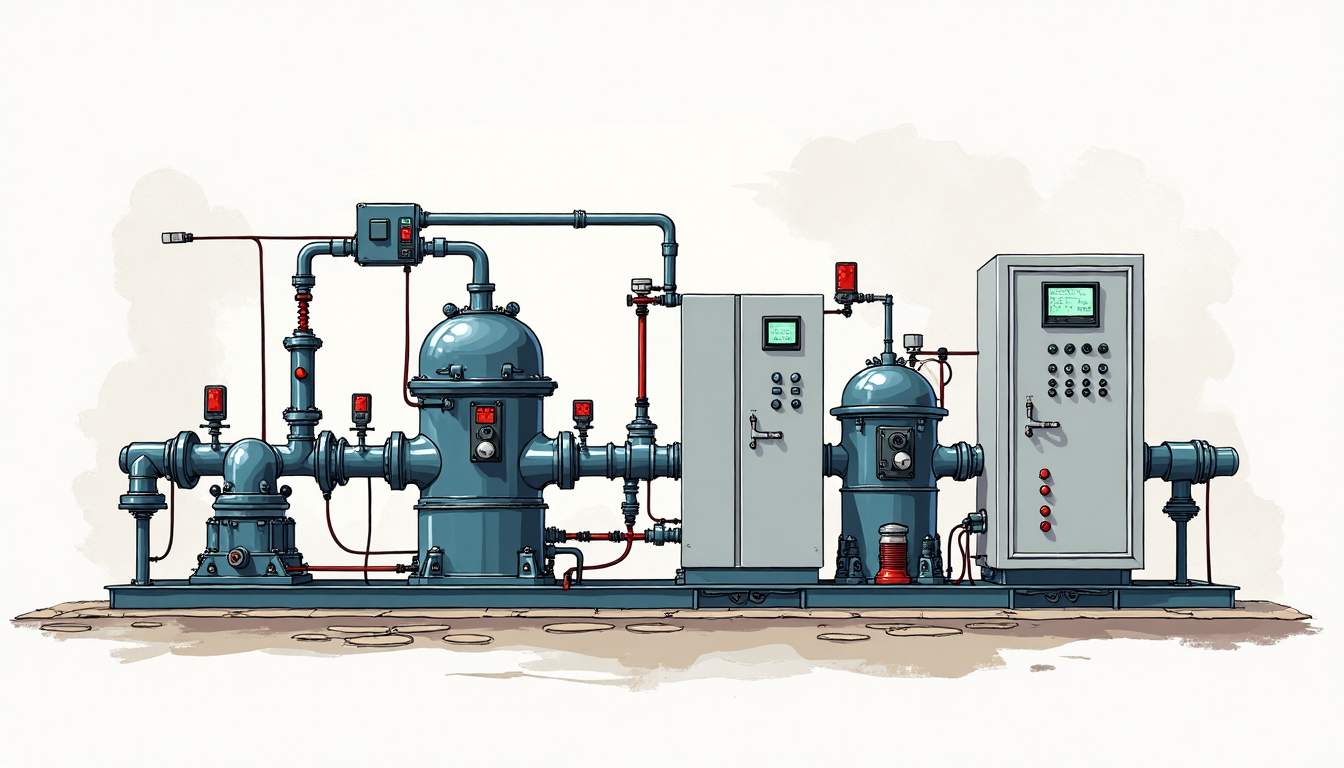

Understanding the components of a pump alarm system is vital for effective implementation. Key elements include sensors, controllers, alarms, and communication interfaces. Each component plays a specific role in monitoring and responding to pump conditions.

Sensors are responsible for detecting changes in parameters such as pressure, temperature, and flow. Controllers process this information and determine whether an alarm condition exists. Alarms, which can be visual or auditory, alert operators to potential issues. Finally, communication interfaces enable remote monitoring and integration with other systems.

In addition to these primary components, advanced pump alarm systems may also incorporate data logging features, which record historical performance metrics. This data can be invaluable for troubleshooting and optimizing pump performance over time. Furthermore, many modern systems utilize cloud-based technologies, allowing for enhanced data analytics and remote access. This capability not only facilitates better decision-making but also supports compliance with regulatory standards by providing detailed reports on pump operations and incidents.

Types of Pump Alarm Systems

There are various types of pump alarm systems, each tailored to specific applications and environments. Understanding these types can help organizations select the most appropriate system for their needs.

Mechanical Alarm Systems

Mechanical alarm systems rely on physical components to detect changes in pump conditions. These systems often include pressure switches and float switches that activate alarms when certain thresholds are exceeded. While mechanical systems are generally simple and cost-effective, they may lack the sophistication of electronic alternatives. Additionally, mechanical systems can be more prone to wear and tear over time, especially in harsh environments, which may necessitate more frequent maintenance. Their straightforward design, however, makes them easy to troubleshoot, allowing operators to quickly identify and rectify issues without needing specialized training.

Electronic Alarm Systems

Electronic alarm systems utilize advanced technology to monitor pump conditions. They often feature programmable logic controllers (PLCs) or microcontrollers that provide greater flexibility and functionality. These systems can integrate with other monitoring solutions, allowing for comprehensive data analysis and reporting. Furthermore, electronic systems can be programmed to send alerts via email or SMS, ensuring that operators are notified of potential issues even when they are off-site. This capability is invaluable for facilities that operate continuously, as it allows for proactive management of pump performance and minimizes the risk of downtime due to unexpected failures.

Wireless Alarm Systems

Wireless alarm systems offer the advantage of remote monitoring without the need for extensive wiring. These systems use wireless sensors and communication protocols to transmit data to a central control unit. This flexibility is particularly beneficial in applications where traditional wiring may be challenging or costly. Moreover, wireless systems can be easily expanded or modified, making them ideal for dynamic environments where pump configurations may change frequently. The ability to access real-time data from a mobile device or computer enhances operational efficiency, allowing for immediate responses to alarms and better overall management of pump systems. As technology continues to evolve, many wireless alarm systems are also incorporating IoT capabilities, enabling even more sophisticated monitoring and control options that can lead to improved performance and energy savings.

How Pump Alarm Systems Work

Understanding how pump alarm systems operate is crucial for effective monitoring and maintenance. The functionality of these systems can be broken down into several key processes.

Monitoring Parameters

At the core of any pump alarm system is the continuous monitoring of critical parameters. Sensors are strategically placed to track variables such as pressure, temperature, and flow rate. When these parameters deviate from predefined thresholds, the system recognizes a potential issue. Advanced systems may also incorporate additional sensors to monitor vibration and electrical consumption, providing a more comprehensive overview of pump health. This multi-faceted approach ensures that even subtle changes in performance are detected early, allowing for timely intervention and reducing the risk of catastrophic failures.

Triggering Alarms

Once a deviation is detected, the controller processes the information and determines whether to activate an alarm. Alarms can be configured to trigger at different levels, such as warning and critical alerts. This tiered approach allows operators to prioritize responses based on the severity of the situation. In addition to audible alarms, many systems also offer visual indicators, such as flashing lights or digital displays, to ensure that alerts are noticed promptly. Some sophisticated alarm systems even integrate with mobile applications, sending notifications directly to operators’ smartphones, thereby enhancing response times and facilitating remote monitoring.

Data Logging and Reporting

Many modern pump alarm systems include data logging capabilities, recording historical data for analysis. This information can be invaluable for identifying trends, diagnosing recurring issues, and optimizing pump performance. Reports generated by the system can aid in maintenance planning and decision-making. Furthermore, with the advent of cloud-based technologies, data can be accessed remotely, allowing for real-time analysis and collaboration among maintenance teams. This capability not only streamlines the maintenance process but also empowers organizations to implement predictive maintenance strategies, reducing downtime and extending the lifespan of their pumping equipment.

Benefits of Implementing Pump Alarm Systems

The advantages of installing a pump alarm system extend beyond immediate safety concerns. Organizations can reap numerous benefits that contribute to overall operational efficiency and cost savings.

Enhanced Safety

One of the primary benefits of pump alarm systems is enhanced safety. By providing real-time alerts, these systems enable quick responses to potentially hazardous situations. This proactive approach reduces the risk of accidents, protecting both personnel and equipment. Furthermore, many modern pump alarm systems are equipped with advanced sensors that can detect not only mechanical failures but also environmental hazards such as leaks or spills. This added layer of protection ensures that organizations can maintain compliance with safety regulations and avoid potential legal liabilities.

Improved Operational Efficiency

With continuous monitoring and timely alerts, pump alarm systems help maintain optimal pump performance. This leads to reduced downtime and increased productivity. By addressing issues before they escalate, organizations can ensure that their operations run smoothly. Additionally, these systems often come with data logging capabilities, allowing operators to analyze performance trends over time. This data can be invaluable for predictive maintenance, enabling organizations to schedule repairs during off-peak hours and further optimize their operational workflow.

Cost Savings

Investing in a pump alarm system can lead to significant cost savings over time. By preventing equipment failures and minimizing downtime, organizations can avoid costly repairs and lost revenue. Additionally, improved efficiency can result in lower energy consumption, further reducing operational costs. The integration of smart technology in these systems also allows for remote monitoring and control, which can eliminate the need for on-site personnel to constantly oversee pump operations. This not only cuts labor costs but also allows staff to focus on more strategic tasks, enhancing overall workplace productivity.

Best Practices for Pump Alarm System Implementation

To maximize the effectiveness of a pump alarm system, organizations should follow best practices during the implementation process. These practices ensure that the system operates optimally and meets the specific needs of the facility.

Conduct a Needs Assessment

Before selecting a pump alarm system, it is essential to conduct a thorough needs assessment. This process involves evaluating the specific requirements of the facility, including the types of pumps used, the environment, and regulatory compliance. Understanding these factors will help in selecting the most suitable system. Additionally, engaging with stakeholders, including operators and maintenance personnel, can provide valuable insights into potential challenges and operational nuances that may not be immediately apparent. This collaborative approach fosters a sense of ownership among staff, which can enhance the effectiveness of the system once implemented.

Choose the Right System

Based on the needs assessment, organizations should choose a pump alarm system that aligns with their operational goals. Considerations should include the type of alarms, monitoring capabilities, and integration options with existing systems. Selecting a system that can grow with the organization is also crucial for long-term success. Furthermore, it is beneficial to evaluate the user interface and ease of use of the system, as a more intuitive design can significantly reduce training time and improve response rates during alarm events. Organizations should also consider the availability of technical support and the reputation of the manufacturer, as these factors can greatly influence the system's reliability and longevity.

Regular Maintenance and Testing

Once the pump alarm system is in place, regular maintenance and testing are vital for ensuring its reliability. Routine inspections and functional tests should be conducted to verify that sensors and alarms are working correctly. This proactive approach minimizes the risk of system failure when it is needed most. In addition to scheduled maintenance, organizations should establish a log of all tests and repairs to track performance over time. This documentation can be invaluable for identifying patterns or recurring issues, which can inform future upgrades or adjustments to the system. Training personnel on emergency response procedures in conjunction with the alarm system is equally important, as it prepares staff to act swiftly and effectively in the event of an alarm activation, thereby safeguarding both equipment and personnel.

Challenges and Considerations

While pump alarm systems offer numerous benefits, organizations must also be aware of potential challenges and considerations associated with their implementation.

Integration with Existing Systems

Integrating a new pump alarm system with existing infrastructure can present challenges. Compatibility issues may arise, requiring additional resources for seamless integration. It is essential to work with experienced professionals who can ensure that the new system functions effectively within the existing framework. Furthermore, organizations should conduct a thorough assessment of their current systems to identify any potential gaps or conflicts that could hinder integration. This proactive approach can save time and resources in the long run, allowing for a smoother transition and minimizing disruptions to operations.

Training and User Adoption

Successful implementation of a pump alarm system relies on user adoption. Operators must be adequately trained to understand the system’s functionalities and respond appropriately to alarms. Investing in training programs can enhance user confidence and ensure that the system is utilized to its full potential. Beyond initial training sessions, ongoing support and refresher courses can help maintain a high level of competency among users. Additionally, fostering a culture of open communication where operators feel comfortable sharing their experiences and challenges with the system can lead to continuous improvement and increased operational efficiency.

Cost Considerations

While the long-term benefits of pump alarm systems are clear, organizations must also consider the initial investment. Budget constraints may limit options, making it essential to weigh the costs against potential savings. A well-planned investment strategy can help organizations make informed decisions. It is also important to consider the total cost of ownership, which includes maintenance, potential upgrades, and training expenses over time. By evaluating these factors, organizations can better understand the financial implications and set realistic expectations for return on investment. Additionally, exploring financing options or incentives for adopting advanced technologies may provide further opportunities to mitigate upfront costs while enhancing operational reliability.

Future Trends in Pump Alarm Systems

The landscape of pump alarm systems is continually evolving, driven by advancements in technology and changing industry needs. Staying informed about future trends can help organizations remain competitive and enhance their operational capabilities.

Integration with IoT Technology

The Internet of Things (IoT) is revolutionizing industrial operations, including pump monitoring. Future pump alarm systems are likely to incorporate IoT technology, enabling real-time data access and remote monitoring. This integration will enhance decision-making capabilities and streamline maintenance processes. Furthermore, with the ability to connect multiple devices and sensors, operators can gain a holistic view of their systems, allowing for better resource allocation and quicker response times in case of anomalies. The seamless flow of information between devices will also foster collaboration among teams, as they can share insights and make informed decisions based on comprehensive data analysis.

Advanced Data Analytics

As data collection becomes more sophisticated, pump alarm systems will leverage advanced analytics to provide deeper insights. Predictive analytics can identify potential issues before they occur, allowing for proactive maintenance strategies. This shift from reactive to predictive maintenance will significantly enhance operational efficiency. Moreover, machine learning algorithms can continuously improve the accuracy of predictions by learning from historical data and adapting to new patterns. This not only reduces downtime but also extends the lifespan of the equipment, ultimately leading to cost savings and improved reliability. Organizations will increasingly rely on these analytics to optimize their workflows and ensure that their pump systems operate at peak performance.

Increased Focus on Sustainability

With growing concerns about environmental impact, future pump alarm systems will likely prioritize sustainability. This includes optimizing energy consumption and minimizing waste. Organizations that adopt eco-friendly practices will not only comply with regulations but also enhance their reputation in the marketplace. Additionally, the incorporation of renewable energy sources, such as solar or wind power, into pump operations can further reduce carbon footprints. As sustainability becomes a core value for many businesses, the demand for pump alarm systems that support green initiatives will likely increase, driving innovation in energy-efficient technologies and practices. This trend will not only benefit the environment but also appeal to a more eco-conscious consumer base, creating a competitive edge in the industry.

Conclusion

In conclusion, pump alarm systems are vital for ensuring the safe and efficient operation of pumps across various industries. By understanding their components, functionalities, and benefits, organizations can make informed decisions about implementation. Adopting best practices and staying abreast of future trends will further enhance the effectiveness of these systems, ultimately leading to improved safety, efficiency, and cost savings.

Investing in a reliable pump alarm system is not just a technical decision; it is a strategic move that can significantly impact an organization's operational success. As industries continue to evolve, the role of pump alarm systems will only become more critical in maintaining smooth and safe operations.