Asset management is a critical aspect of the wastewater industry, especially for maintenance technicians responsible for ensuring the smooth operation of their facility. In this comprehensive guide, we will explore the basics of asset management, the key principles that drive effective strategies, and the steps to implement and overcome challenges in asset management. We will also discuss the role of technology and future trends in this field. By the end of this guide, you will have a thorough understanding of asset management and its significance in the wastewater industry.

Understanding the Basics of Asset Management

Asset management refers to the systematic and strategic approach of managing assets to maximize their value and ensure their long-term performance. In the wastewater industry, assets encompass a broad range of physical and non-physical components such as pumps, pipes, treatment plants, and even data systems. By effectively managing these assets, maintenance technicians can optimize their lifespan, minimize downtime, and reduce costs.

However, asset management in the wastewater industry goes beyond simply maintaining physical infrastructure. It also involves managing intangible assets such as knowledge, skills, and information systems. Maintenance technicians need to have a comprehensive understanding of the entire asset lifecycle, from planning and acquisition to operation and disposal.

When it comes to asset management, one of the key challenges faced by maintenance technicians is prioritizing tasks. With numerous assets to manage and limited resources, it is crucial to identify critical assets that require immediate attention. This is where data-driven decision-making becomes essential. By analyzing data on asset performance, maintenance technicians can identify patterns, predict failures, and allocate resources effectively.

Defining Asset Management in the Wastewater Industry

In the wastewater industry, asset management is not just about maintaining physical assets. It also involves managing the complex network of pipes, valves, and pumps that transport and treat wastewater. Additionally, it includes the management of data systems that collect and analyze information related to asset performance and maintenance activities.

Effective asset management in the wastewater industry requires a multidisciplinary approach. It involves collaboration between maintenance technicians, engineers, data analysts, and other stakeholders. By working together, these professionals can develop comprehensive asset management plans that consider factors such as asset condition, risk, and cost.

Importance of Asset Management for Maintenance Technicians

Maintenance technicians play a crucial role in asset management. They are responsible for the regular inspection, maintenance, and repair of assets to ensure their optimal functioning. By implementing effective asset management strategies, maintenance technicians can streamline their work processes, prioritize tasks, and make data-driven decisions. This not only improves operational efficiency but also enhances the overall reliability and safety of the wastewater facility.

Furthermore, asset management helps maintenance technicians extend the lifespan of assets. By identifying potential issues early on and addressing them promptly, technicians can prevent costly breakdowns and avoid unplanned downtime. This proactive approach to maintenance not only saves time and money but also minimizes the impact on the environment by reducing the risk of wastewater spills or leaks.

In conclusion, asset management is a critical aspect of wastewater facility operations. It involves the strategic management of physical and non-physical assets to maximize their value and ensure long-term performance. By implementing effective asset management strategies, maintenance technicians can optimize asset lifespan, minimize downtime, and reduce costs. This ultimately leads to improved operational efficiency, enhanced reliability, and increased safety in the wastewater industry.

Key Principles of Effective Asset Management

Asset management is a complex process that involves various principles and strategies to ensure the optimal performance and longevity of assets. In this article, we will explore three key principles that are fundamental to effective asset management.

Lifecycle Management of Assets

One of the fundamental principles of asset management is to consider the entire lifecycle of an asset. This involves planning, designing, procuring, operating, maintaining, and eventually decommissioning the asset in a systematic manner. By taking a holistic approach, maintenance technicians can optimize asset performance, minimize downtime, and reduce lifecycle costs.

During the planning phase, technicians carefully analyze the requirements and objectives of the asset, considering factors such as expected lifespan, usage patterns, and maintenance needs. This information is then used to design and procure the asset, ensuring that it meets the specific operational requirements and industry standards.

Once the asset is in operation, maintenance technicians play a crucial role in maintaining its performance and reliability. Regular inspections, preventive maintenance, and timely repairs are essential to extend the asset's lifespan and minimize unexpected failures. By implementing a well-defined maintenance strategy, technicians can proactively address potential issues and ensure the asset operates at its optimal level.

As the asset approaches the end of its useful life, technicians must carefully plan for its decommissioning. This involves safely removing and disposing of the asset, considering environmental regulations and sustainability practices. By managing the entire lifecycle of an asset, maintenance technicians can maximize its value and minimize the impact on the environment.

Risk and Performance Based Decision Making

Another key principle of asset management is to base decisions on risk and performance assessments. Maintenance technicians need to identify and evaluate potential risks associated with assets, such as failure rates and criticality. By prioritizing maintenance activities based on these assessments, technicians can allocate resources effectively and ensure the highest level of performance and safety for their assets.

Risk assessments involve analyzing various factors that can impact asset performance, including operational conditions, environmental factors, and the consequences of failure. By quantifying and prioritizing these risks, technicians can develop a risk management plan that focuses on mitigating the most critical risks first.

Performance assessments, on the other hand, involve monitoring and analyzing the asset's performance indicators, such as reliability, availability, and maintainability. By continuously monitoring these metrics, technicians can identify potential performance issues and take proactive measures to improve asset performance.

By combining risk and performance assessments, maintenance technicians can make informed decisions regarding maintenance activities, such as scheduling inspections, replacing components, or implementing upgrades. This approach ensures that resources are allocated efficiently, minimizing downtime, and maximizing asset performance.

Continuous Improvement and Adaptation

Continuous improvement is essential in asset management. Maintenance technicians should constantly analyze data, monitor asset performance, and identify areas for improvement. By implementing feedback mechanisms and adapting strategies accordingly, technicians can optimize asset reliability, minimize reactive maintenance, and enhance the overall efficiency of their operations.

One way to drive continuous improvement is through the use of data analytics and predictive maintenance techniques. By collecting and analyzing data from various sources, such as sensors, maintenance records, and historical performance data, technicians can identify patterns and trends that can help predict potential failures or performance degradation. This allows technicians to take proactive measures to prevent failures and optimize maintenance activities.

Feedback mechanisms, such as regular meetings and surveys with maintenance teams and end-users, are also crucial in identifying areas for improvement. By actively seeking feedback and suggestions, technicians can gain valuable insights into the asset's performance and identify opportunities to enhance its reliability and efficiency.

Furthermore, asset management strategies should be adaptable to changing circumstances and technological advancements. As new technologies emerge, maintenance technicians should evaluate their potential benefits and incorporate them into their asset management practices. This adaptability ensures that asset management strategies remain effective and aligned with the evolving needs of the organization.

In conclusion, effective asset management requires a comprehensive understanding of the asset's lifecycle, a risk-based approach to decision making, and a commitment to continuous improvement. By implementing these key principles, maintenance technicians can optimize asset performance, minimize downtime, and enhance the overall efficiency of their operations.

Asset Management Strategies for the Wastewater Industry

The wastewater industry relies on effective asset management strategies to ensure the smooth operation of treatment processes and minimize disruptions. In this article, we will explore three key strategies: preventive maintenance, predictive maintenance, and reliability-centered maintenance.

Preventive Maintenance Strategy

Preventive maintenance is a widely adopted strategy in the wastewater industry. It involves performing routine inspections, servicing, and replacements according to a predetermined schedule. By proactively addressing potential issues, maintenance technicians can prevent breakdowns, extend asset lifecycles, and minimize the impact on wastewater treatment processes.

For example, in a wastewater treatment plant, preventive maintenance may involve regular inspections of pumps, valves, and motors to check for any signs of wear or damage. Technicians may also perform routine lubrication, calibration, and cleaning to ensure optimal equipment performance. By adhering to a preventive maintenance schedule, potential problems can be identified and resolved before they escalate into costly failures.

Predictive Maintenance Strategy

Predictive maintenance takes asset management a step further by using advanced data analysis techniques to anticipate failures. By collecting and analyzing real-time data from sensors and monitoring systems, maintenance technicians can detect early signs of equipment degradation or malfunctions. This allows for targeted maintenance interventions, reducing unplanned downtime and optimizing operational efficiency.

For instance, in a wastewater treatment facility, predictive maintenance may involve the use of condition monitoring sensors to track variables such as vibration, temperature, and pressure. By analyzing these data points, maintenance technicians can identify patterns and trends that indicate potential equipment failures. This enables them to schedule maintenance activities at the most opportune times, minimizing disruptions to the treatment process.

Reliability-Centered Maintenance Strategy

Reliability-centered maintenance focuses on identifying and prioritizing critical assets based on their impact on overall system performance. By implementing condition-based monitoring, reliability-centered maintenance enables maintenance technicians to prioritize resources, optimize spare parts inventory, and ensure asset reliability where it matters most.

For example, in a wastewater treatment plant, reliability-centered maintenance may involve conducting risk assessments to determine the criticality of different assets. By considering factors such as asset age, historical failure rates, and consequences of failure, technicians can allocate resources to the most critical assets. This approach ensures that limited resources are utilized effectively, minimizing the potential for system failures and optimizing the overall performance of the wastewater treatment facility.

In conclusion, asset management strategies play a crucial role in the wastewater industry. Preventive maintenance, predictive maintenance, and reliability-centered maintenance are all valuable approaches that help ensure the reliable and efficient operation of wastewater treatment processes.

Implementing Asset Management in Wastewater Operations

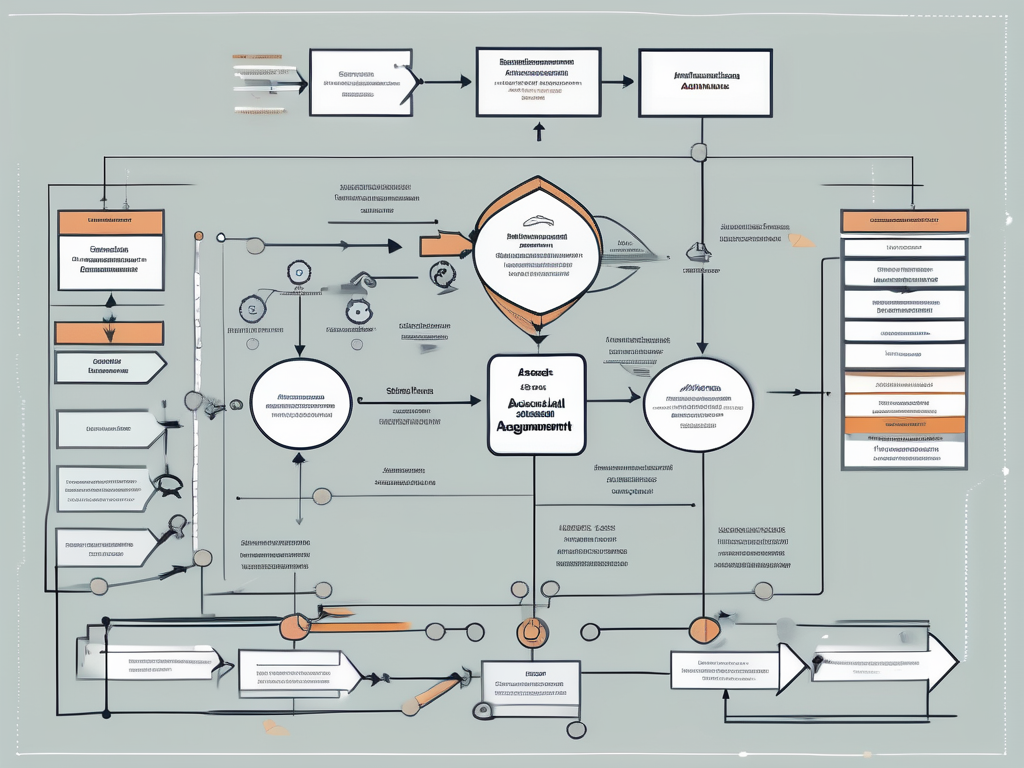

Asset management is a crucial aspect of wastewater operations. It involves the systematic and strategic approach to managing assets to achieve optimal performance, minimize risks, and ensure long-term sustainability. Implementing an asset management plan requires careful planning and execution. The following steps can guide maintenance technicians in the implementation process:

- Define asset management objectives and goals: Before embarking on the implementation journey, it is essential to clearly define the objectives and goals of the asset management plan. This step helps align the plan with the overall organizational strategy and ensures that everyone is working towards a common vision.

- Conduct an asset inventory and assessment: To effectively manage assets, it is crucial to have a comprehensive understanding of what assets are in place and their current condition. Conducting an asset inventory and assessment helps identify critical assets, assess their condition, and prioritize maintenance activities.

- Develop a maintenance strategy based on asset criticality: Not all assets have the same level of criticality. Some assets are more vital to the operation and require more frequent and intensive maintenance. By categorizing assets based on their criticality, maintenance technicians can develop a targeted maintenance strategy that optimizes resources and ensures the reliability of critical assets.

- Establish key performance indicators and monitoring systems: Key performance indicators (KPIs) are essential metrics that help measure the effectiveness of asset management efforts. By establishing KPIs and implementing monitoring systems, maintenance technicians can track performance, identify areas for improvement, and make data-driven decisions.

- Allocate resources and plan maintenance activities: Adequate allocation of resources is crucial for successful asset management. This includes assigning skilled personnel, procuring necessary tools and equipment, and budgeting for maintenance activities. By carefully planning and scheduling maintenance activities, technicians can ensure that assets are properly maintained and downtime is minimized.

- Integrate asset management into existing workflows and systems: Asset management should not be a standalone process but rather integrated into existing workflows and systems. By aligning asset management practices with other operational processes, such as work order management and inventory control, maintenance technicians can streamline operations and improve efficiency.

- Regularly review, analyze, and adapt the asset management plan: Asset management is an ongoing process that requires continuous improvement. Maintenance technicians should regularly review and analyze the asset management plan, identify areas for enhancement, and adapt the plan to changing circumstances. This iterative approach ensures that the asset management plan remains effective and aligned with organizational goals.

Overcoming Challenges in Asset Management Implementation

Implementing asset management strategies can be challenging, especially in the wastewater industry. However, with the right approach and mindset, these challenges can be overcome. Some common challenges include:

- Limited budget and resources: Wastewater utilities often face budget constraints and limited resources. To overcome this challenge, maintenance technicians should focus on building a strong business case for asset management, highlighting the potential cost savings and improved operational efficiency that can be achieved.

- Lack of data standardization and integration: Wastewater operations generate vast amounts of data, but often this data is not standardized or integrated into a central system. To address this challenge, maintenance technicians should advocate for data standardization and invest in technology solutions that enable seamless data integration and analysis.

- Legacy systems and outdated technology: Many wastewater utilities still rely on legacy systems and outdated technology, which can hinder effective asset management. To overcome this challenge, maintenance technicians should advocate for investment in modern technology solutions that enable real-time monitoring, predictive maintenance, and data-driven decision-making.

- Resistance to change and lack of support from stakeholders: Implementing asset management requires a cultural shift within the organization. Resistance to change and lack of support from stakeholders can pose significant challenges. To address this, maintenance technicians should focus on fostering a culture of collaboration and continuous improvement, engaging stakeholders in the decision-making process, and showcasing the benefits of asset management.

By addressing these challenges head-on and implementing effective strategies, maintenance technicians can successfully implement asset management in wastewater operations, leading to improved asset performance, reduced risks, and enhanced operational efficiency.

Role of Technology in Asset Management

Impact of Digitalization on Asset Management

Advancements in technology have revolutionized asset management in the wastewater industry. Digitalization enables maintenance technicians to collect, analyze, and interpret vast amounts of data in real-time. By leveraging technologies such as remote sensing, data analytics, and machine learning, maintenance technicians can make data-driven decisions, optimize maintenance schedules, and detect potential failures before they occur.

Utilizing IoT for Efficient Asset Management

The Internet of Things (IoT) has unlocked new possibilities for asset management. By connecting assets and sensors to a network, maintenance technicians can remotely monitor and control their performance. IoT-enabled asset management provides real-time insights into asset health, enables predictive maintenance, and facilitates remote troubleshooting, leading to improved efficiency and reduced costs.

Future Trends in Asset Management for the Wastewater Industry

Sustainability and Asset Management

With increasing environmental concerns, sustainable asset management is gaining importance in the wastewater industry. Maintenance technicians are expected to prioritize energy efficiency, minimize waste generation, and incorporate renewable technologies into their asset management strategies. By adopting sustainable practices, organizations can reduce their environmental footprint and achieve long-term operational sustainability.

The Role of AI and Machine Learning in Asset Management

Artificial intelligence (AI) and machine learning are poised to shape the future of asset management. These technologies can analyze vast amounts of historical and real-time data to identify patterns, anomalies, and optimal maintenance strategies. AI-powered asset management systems can enhance asset performance, reduce downtime, and enable technicians to make accurate predictions and timely interventions.

By following the principles and implementing the strategies discussed in this guide, maintenance technicians in the wastewater industry can establish effective asset management practices. By embracing technology and staying abreast of future trends, they can ensure the optimal performance, reliability, and sustainability of their assets. Remember, asset management is a continuous journey, and by investing time and effort in this field, maintenance technicians can contribute to the overall success of their organization in the wastewater industry.